WHAT ARE NONWOVENS?

Nonwovens (technical textiles) are engineered fabrics made from synthetic and/or natural fibers bonded together by mechanical, thermal or chemical treatment.

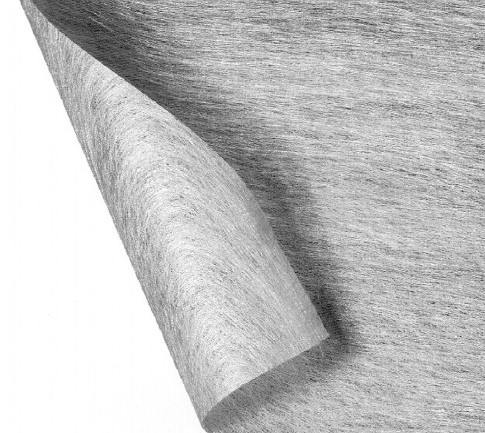

Spunbonded nonwovensSpunbonded fabrics are manufactured from continuous filaments and being spun from extruded polymers. Spunbonded fabrics are unique due to the fact that they are stronger than other types of nonwovens. Spunbonded fabrics have weights ranging from 12 up to 300 g/m². For the manufacturing of spunbonds the following polymers can be used: PP, PE, PET and PLA. Spunbonded nonwovens can be coated or laminated, but also special features can be added such as UV stability, flame retardant, hydrophobic or hydrophilic. |

|

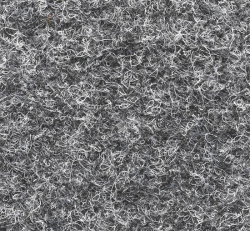

Needle Punched nonwovensNeedle punched nonwovens are manufactured from staple fibers. During the mechanical carding process, a web is formed. Specifically designed needles are pushed and pulled through the web to entangle the fibers. By choosing the type of fiber, the way of needling and thermal treatment, a wide range of variety needle punched nonwovens can be produced. Needle punched nonwoven has weights ranging from 70 up to 3000 g/m². For the manufacturing of needle punched nonwovens following materials can be used: PP, PET, PLA, but also natural fibers, such as viscose, jute, wool, hemp. Needle punched fabrics can be coated or laminated, but also special features can be added such as UV stability, flame retardant, hydrophobic or hydrophilic. |

|

Thermal bonded nonwovens

Thermal bonded fabrics are manufactured from staple fibers. Similar to needle punch fabrics, a fibrous web is obtained through a carding process. However, these fibers are bonded by a thermal treatment. Thermal bonded nonwovens are available from 20 g/m² and are applied in a.o. the cable industry.

Chemical bonded nonwovens

Chemical bonded fabrics are also manufactured from staple fibers and also through a carding process, a fibrous web is obtained. This nonwoven is accomplished by adding a chemical binder. These impregnated fibers are then being run through an oven for thermal treatment, what remains is a chemically bonded textile. Chemical bonded nonwovens are available from 30 g/m² and are applied in a.o, cables wipes, surgical gowns and disposable table cloths.